What is Diapers, Sanitary Pads and Tampons

All absorbent hygiene products are designed principally to contain body fluids such as urine or menstrual fluid. The ability to contain feces is also an important attribute in baby diapers and some incontinence products.

Whilst individual absorbent hygiene product groups may have differing fit and use requirements, the basic fluid management structure follows similar principles in all categories. Fluid must be readily accepted, distributed and absorbed by the structure. Layered constructions and various materials are used to engineer these in-use performance requirements precisely. Materials selected must have appropriate properties and skin contact materials should be suitable for prolonged intimate use.

There are four principal functional layers, each of which is engineered to optimize overall product performance.

Topsheet or FacingThe layer next to the user’s skin must be capable of allowing fluid to pass readily through to the next layer. It is important that fluid is not retained within the structure of this layer so that the amount of time that moisture is in contact with the skin is kept to the minimum. Softness of feel is a critical attribute for skin contact material.

Acquisition and Distribution Layer(ADL) Fluid passes through the topsheet into the Acquisition and Distribution Layer where it is temporarily stored whilst capillary action causes it to spread over a larger area. This facilitates maximum utilization of the absorbent core structure. As most Superabsorbent Polymers (SAP) can take a few moments to fully absorb fluid, the ADL plays an important role in managing fluid during this critical stage. Any absorbent hygiene product with a high superabsorbent and low fluff pulp content, such as a baby diaper, will place high demands on ADL performance. Products with high fluff pulp or low SAP levels can often function without a separate ADL due to the good capillary properties of the fluff fibers.

Absorbent CoreThe fluid storage layer typically relies on an appropriate blend of fiberized fluff pulp and superabsorbent polymer to absorb and retain urine or menstrual fluids. Total capacity can be engineered to a level appropriate for any individual product application. Twin cores can also be used to manage high fluid levels in heavy incontinence products. Many modern ‘ultra thin’ feminine hygiene products use an engineered airlaid substrate as an absorbent layer. This is generally a pre-combined structure of multiple layers, containing both SAP and fluff pulp or other suitable capillary fibers. The resultant product is extremely thin and discreet in use.

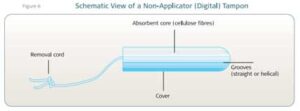

The absorbent core in modern tampons is made of cellulose-based absorbent material, of either rayon (viscose) or cotton, or a mixture of both.

Backsheet or Outer CoverThe function of the backsheet is to provide a fluid impervious barrier so that moisture is contained within the structure of the absorbent hygiene product. Many types of films are suited to this application, most commonly used is low gauge polyethylene. Many products are subsequently enhanced by the addition of soft nonwoven covers to the polyethylene, which can be colored or printed on to suit market needs. It is also generally accepted that a breathable film or nonwoven layer is of benefit in maintaining good skin condition, particularly in baby diapers and panty liners. Polyethylene can be made breathable at the film extrusion stage by creating micro pores in the substrate, and fibers in the nonwoven layer can be treated to be hydrophobic. These two processes allow air to pass through the film whilst maintaining an effective fluid barrier.

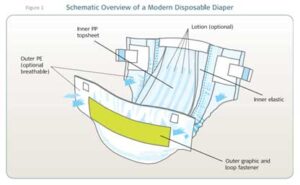

(Figure 1) Whilst the four principal functional layers of an absorbent hygiene product are the main components in baby diapers, other materials are necessary to aid ease of use for the parents and comfort for the child. Modern fastening systems are typically of a hook and loop style, elastic legs and inner cuffs are used to contain feces, and several stretch features may be added to enhance the comfort of the child and fit of the diaper.

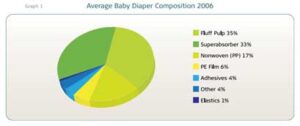

Diapers are made in a wide range of sizes and can fit babies up to 36 months old. There are also many supplementary product ranges available such as training pants and overnight pants to assist in the toilet training process as well as youth diapers for children with ongoing continence problems. A typical maxi-size baby diaper weighs approximately 40-42 grams. Over the last two decades diapers have evolved to become thinner, lighter, and more efficient. The 2006 average diaper composition, as measured through Life Cycle Assessment analysis, is given in graph 1:

There is a wide range of products in this category to suit different people depending on lifestyle, type of condition and body size. All have common performance requirements, namely: dryness, leakage protection, comfort and discretion in use, reduction of odor and helping to prevent skin irritation.

For people with light to medium incontinence there are small panty liners, pads and light pants; some are gender specific, while others are unisex. For people with medium to heavy incontinence problems there are heavy pants, two piece products (pad and pant), all-in-one briefs and belted briefs, (see figure 2). Whilst the four principal functional layers of an absorbent hygiene product are important in all incontinence products, other materials are necessary, depending on the type of product, to aid ease of use for the care giver or nurse and for the comfort of the user; examples are belts, waist elastic, leakage barriers, tape or hook and loop fastening and elastic pants.

The product range manages everything from small drops of urine for an active younger woman to liters of fluid for a severely or double incontinent person in a nursing home. As a result the product weight ranges from a few to more than one hundred grams. It is therefore difficult to generalize about an “average product”. Adult incontinence products typically use the same materials as baby diapers but in different proportions.

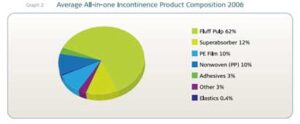

As with baby diapers, continuous innovation has meant that adult incontinence products have been able to become thinner, lighter, and more efficient over the years. The average composition for an all-in-one product is illustrated in graph 2:

Pads and Panty liners Feminine care pads are designed to absorb and retain menstrual fluid and other vaginal discharges and fluids. They come in various sizes for different levels of menstrual flow. They range from panty liners, designed to absorb daily vaginal discharge and light menstrual flow, as a backup for tampon use or for small amounts of urine, to night pads - a longer product designed to provide more protection while the wearer is lying down, with higher absorbency which is more suitable for overnight use.

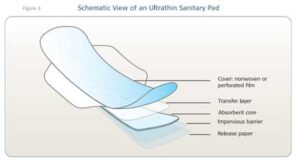

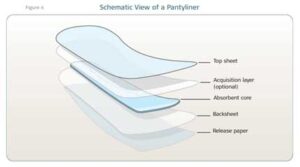

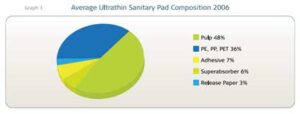

In addition to the four principal functional layers of an absorbent hygiene product, pads and panty liners either have a removable sheet made from siliconized paper which protects the glue underneath the bottom layer or a siliconized polyethylene, which works as a single-wrap protection. The average composition for an ultrathin sanitary pad is illustrated in graph 3, while figures 3 and 4 provide a schematic view of an ultrathin sanitary pad and panty liner.

Modern tampons are mainly composed of cellulose based absorbent material such as rayon or cotton or a mixture of both. In most instances, the absorbent core is covered by a thin, smooth layer of nonwoven or other suitable material, making the tampon easy to insert and remove. The withdrawal cord used to remove the tampon can be made of cotton or polypropylene. The tampon is individually wrapped with a paper wrapper or a thin film before being packed into cartons.

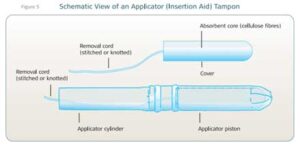

Where an applicator is used it is made of either coated paper or polymers or a combination of both. Like other absorbent product categories they can be engineered by size and absorbent capacity, (see figures 5 and 6).